There’s no time for delays when due dates draw near.

Customers only have so much patience, and they’ll consider competitors if you can’t meet their demands. To avoid reputation-busting bottlenecks and glaring productivity gaps, managers must find ways to keep teams moving at the right pace.

Two metrics from the field of Lean manufacturing — takt time and cycle time — are excellent for determining and maintaining optimal production rates. Incorporating these measurements into your timetables helps improve multiple facets of the production process, including delivery estimates, resource allocation, and scalability efforts.

Learn the distinctions between takt time versus cycle time and how together they offer a complete picture of workflow efficiency.

What’s the difference between cycle time and takt time?

Takt time and cycle time are both measurements that help evaluate and monitor work efficiency, but they measure two different values. The former focuses on the ideal productivity rate to meet scheduled deliveries, while the latter measures a team’s current task completion pace.

What follows is a thorough overview of each time tracking type and how to calculate them.

What’s takt time?

Takt time is a consumer-focused metric popular in manufacturing for estimating the average rate of production relative to current customer demand. Managers determine takt time by following a simple formula, using the result as a guide for monitoring productivity rates.

To determine your takt time, divide your team’s available work hours by the expected customer demand per unit. The days, hours, or minutes in a takt time value give you an estimate of how quickly you need to work per product to satisfy clients. As long as the average production rate stays at or above the takt time, you maintain the pace required to deliver products and keep customers happy.

Suppose a toy manufacturer wants to figure out how to calculate takt time in one month for a customer demand of 5,000 units. First, the manager determines that the working hours at their factory are eight per shift, with 30 shifts per month — or 240 hours. To figure out the takt time, they use the following formula:

240 hours / 5,000 units = 2.88 minutes

This means they have 2.88 minutes to allocate to work per product and must maintain this pace (or a higher one) to keep their workflow on track.

Why is takt time important?

Monitoring takt time ensures the rhythm of your operations stays in line with customer demands. With an accurate takt time measurement, you’re better positioned to spot inefficiencies and adjust workflows.

This metric also helps you:

Set effective work schedules — takt time indicates how much time you need to meet customer demand, helping develop optimal workflow schedules to avoid backlogs and overextended resources. Knowing a team’s takt time makes it easier to identify priorities and assign tasks based on time constraints for efficient and synchronized schedules.

Allocate resources — managers also use takt time to estimate the resources they need to complete their tasks, including labor, materials, and equipment. This resource requirements estimate lets them avoid shortages and overspending.

Maintain efficient scalability — as demand increases, so does the time needed to fulfill customer requests. You can compare these fluctuations in takt time with the average rate of production to craft actionable scalability solutions.

Spot potential production inefficiencies — whenever the average production time per unit exceeds the takt time, companies are at high risk of bottlenecks, delays, and missed delivery targets. Spotting these warning signs early helps leaders introduce solutions, communicate updates with relevant stakeholders, and mitigate damage.

What’s cycle time?

Cycle time measures a team’s current productivity rate. Each cycle time metric highlights how many days, hours, or minutes a company spends completing one task or product cycle.

To learn how to calculate cycle time, managers divide their production time by the units or tasks they complete. So if a marketing department takes 18 hours to produce 15 infographics for social media campaigns, they calculate their cycle time with the following formula:

18 hours / 15 units + 1.2 hours

This time calculation means their current cycle time per infographic is 1.2 hours.

Why is cycle time important?

Reviewing cycle time readings is like taking the pulse of your team’s productivity. With this metric, you have a clearer understanding of where to focus your attention in project management to maintain or improve efficiency.

Knowing your cycle time also helps you:

Screen and optimize efficiently — cycle time offers a glimpse into separate business departments and their average productivity rates, helping you distinguish strengths from weaknesses in the production pipeline. Use this information to tailor efficiency improvements to weaker workstations and maintain high performance throughout strong sectors.

Monitor productivity in real time — knowing your current cycle time helps spot sudden productivity changes, quickly revealing lags or deviations in day-to-day operations. This makes it easier to swoop in with swift problem-solving strategies.

Make data-driven decisions — cycle time estimates are easy to plug into multiple quantitative analyses, which can inform data-driven adjustments to business practices and forecast deliverables. Comparing cycle times among employees and departments also provides data for performance evaluations and informs crucial decisions about hiring, promoting, and letting go of workers.

How do takt time and cycle time interconnect?

Managers often assess takt time and cycle time in tandem to gain a complete overview of team efficiency. By comparing cycle time to takt time, you can see whether your current production rate is high enough to meet expected consumer demands.

This knowledge is crucial when redeveloping or adjusting workflows. When cycle times constantly creep above the takt time, managers must find and fix productivity inefficiencies.

How does lead time differ from takt time and cycle time?

Like takt time and cycle time, lead time is another standard variable in Lean manufacturing for evaluating productivity rates. But with lead time, managers learn the average duration for a product’s entire lifecycle, from a placed order to a received deliverable.

Although lead time shares takt time’s consumer-centric focus, it represents your literal productivity rates in a given product lifecycle rather than a target estimate relative to market demand. And instead of focusing on discrete tasks like cycle time, lead time factors in all project management aspects, including processing, waiting, and shipping.

Determining your lead time provides an end-to-end rate for a deliverable’s lifecycle, so it assists with monitoring the health of your supply chains and maintaining consistency in your workflow tempo. Teams consistently work to reduce their average lead times for higher customer satisfaction, often referencing cycle times to pinpoint delayed operations and implement time-saving efficiencies.

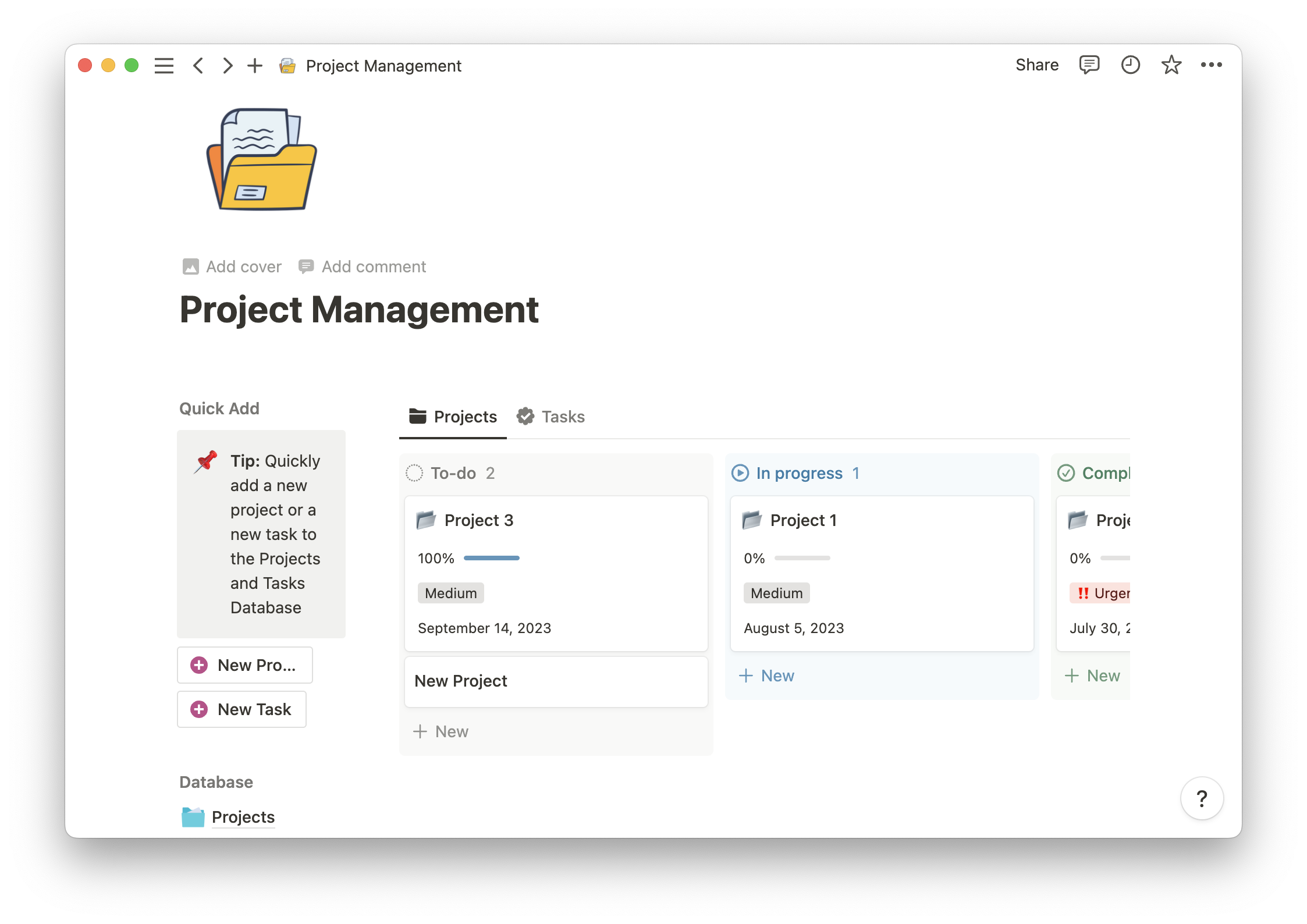

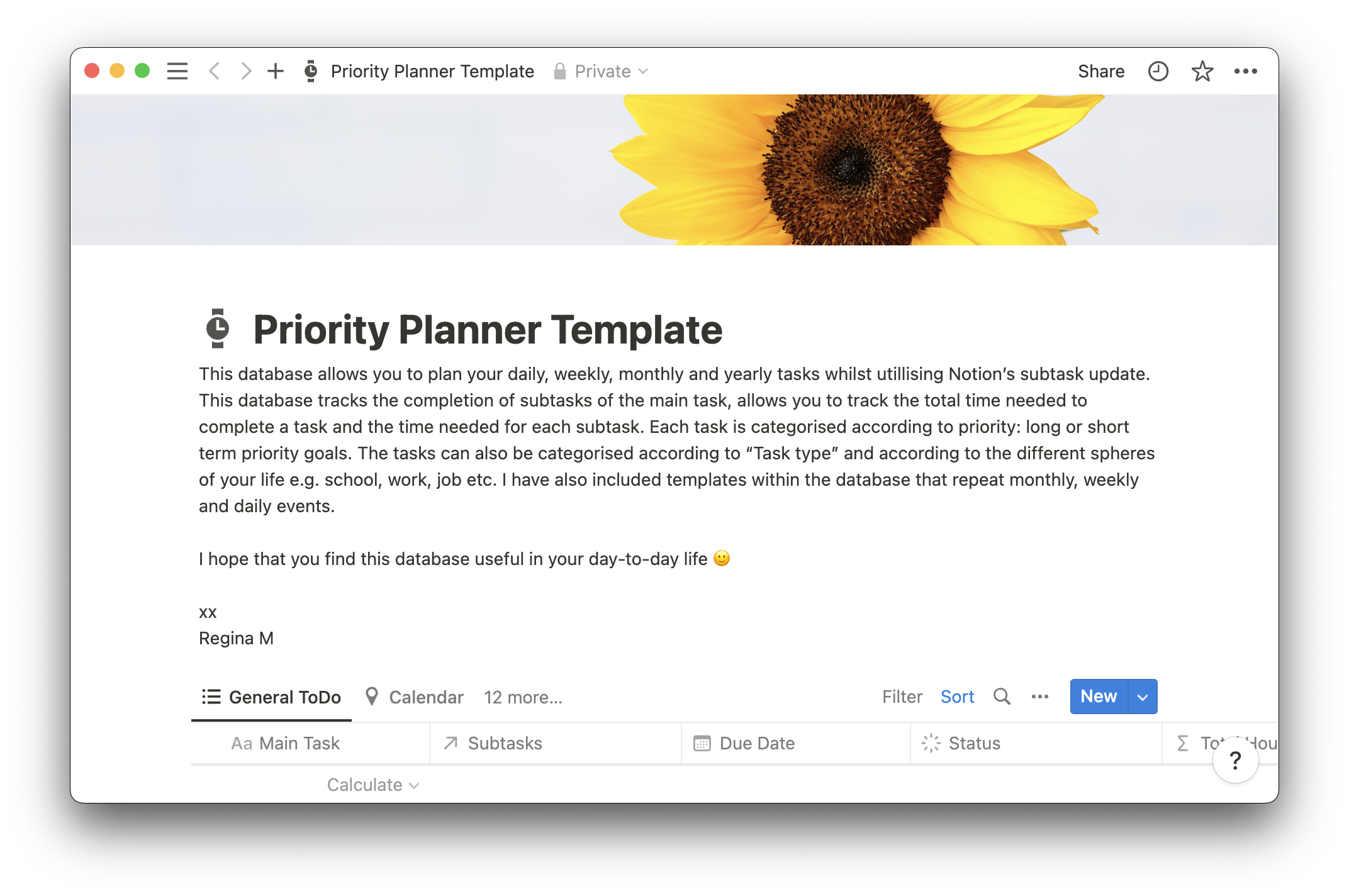

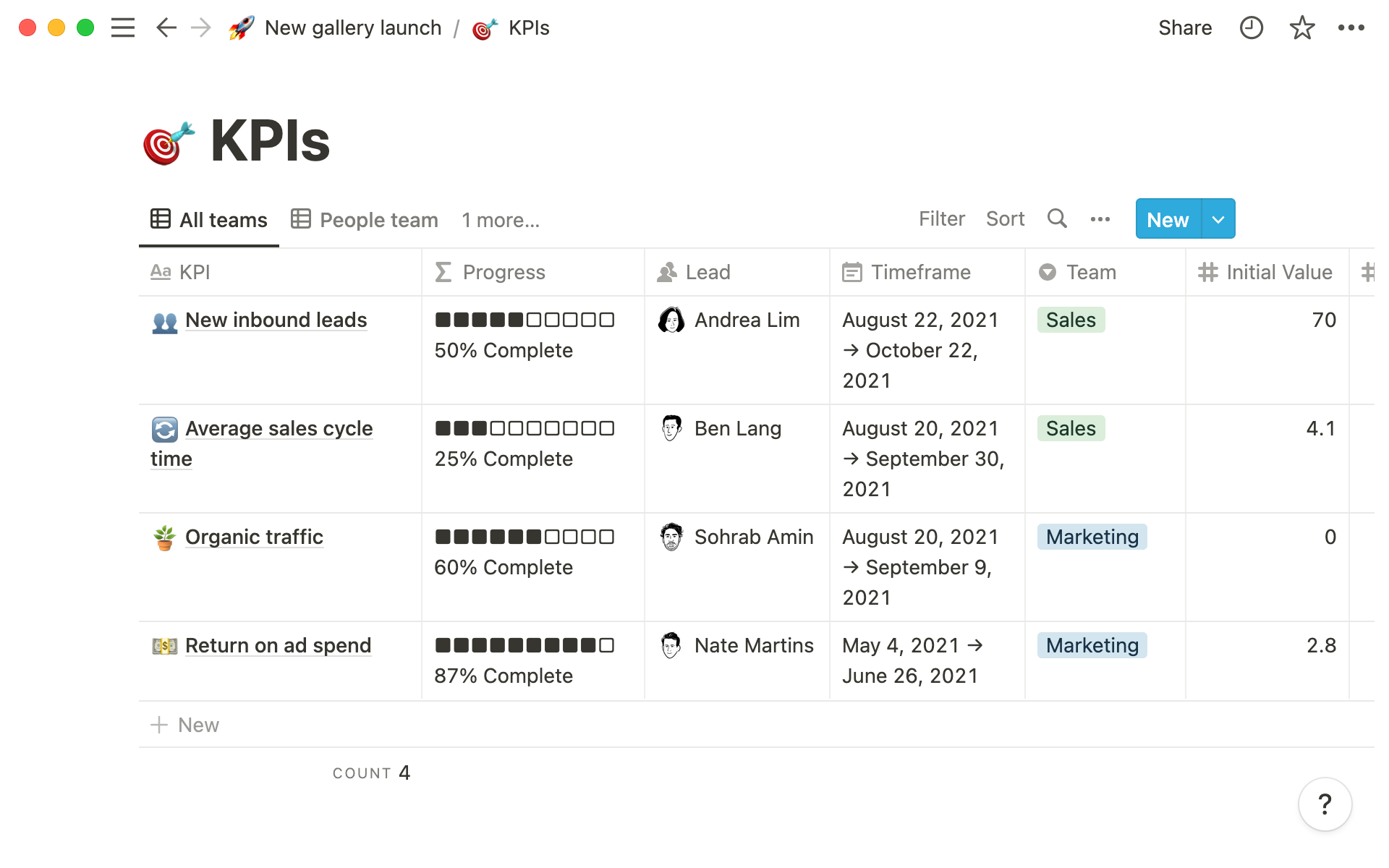

Take control of your workflows with Notion

Metrics like takt time, cycle time, and lead time offer insights into the right rhythm for your company. And you can further track team productivity with Notion’s tools and templates. Resources like project schedules, time trackers, and Gantt charts make it easy to gain a comprehensive view of your project roadmap and average production rates. Find out all the ways Notion puts time on your side by signing up today.